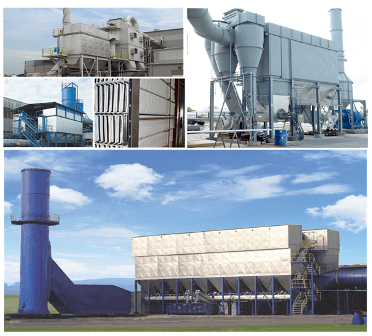

FS Filter

Overview :

The FS filter is a range of compact modular horizontal bag dust collectors particularly suitable for larger industrial plant, especially for handling fine particulate associated with hot gas applications. The flat bag design minimizes the space required and the progressive off-line medium pressure air cleaning system is energy efficient.

Specification :

- Air Flow : 10,000 – 200,000 CFM

Key Features :

- Usable for temperatures up to 250 °C (482 °F)

- Fine dust (PM10, PM 2,5)

- Small space requirements.

- Continuous cleaning

- Customize able to specific applications

- Low maintenance, easy to service

- Reverse air cleaning

Applications :

- Foundry and Aluminum industry

- Asphalt industry

- Cement and Chemicals industry

- Power-generating industry

- Quarries industry

NF Filter

Overview :

The NF filter, baghouse with chain conveyor is suitable for handling large volumes of air with heavy material contamination levels. It is a modular filter made of galvanized steel sheet. Filter has telescopic support and is suitable for outdoor use.

Each module, 2400 mm (94″) of the filter design is fitted with a combined inspection and explosion relief door. Filter cleaning with regeneration fans. The filter is fitted with the unique patented SUPERBAG.

The filter hopper and inlet section (optional) separates medium-sized/large particles and distributes the air to the filter bags. A double chain conveyor on the bottom of the hopper passes the collected material to a rotary valve for discharge.

Specifications :

- Air flow : 6000-500 000 m3/h (3,500-294,000 cfm)

Key Features :

- Suitable for handling large volumes of air with heavy material contamination

- Designed for continuous operation

- Over pressure or vacuum versions up to 5 000 Pa (0.725 psi)

- Powerful online cleaning with efficient regeneration fans

- Easy to install on site and extend when required

- Low energy consumption.

Applications :

- Timber and Wood working machinery

- Furniture production

- Lightweight bulk materials

KS Cooler

Cassette-type heat exchanger with pre-heating of cooling air up to 590C (1,100F).

The cooling air must be preheated if there is any risk of the temperature on the cooling elements dropping below the acid dew point when cooling hot process gases. Nederman has consequently developed the cassette-type KU cooler specifically for cooling such gases.Automatic Cleaning system for sticky dusts

- All elements accessed from the catwalk

- Ability to pre-heat cooling air to eliminate condensation issues

- Low-profile and compact

- No Fluids Needed

- Self Cleaning Option

- Customizable

- Small Footprint

- Fully Automatic Operation

The cooling air must be preheated if there is any risk of the temperature on the cooling elements dropping below the acid dew point when cooling hot process gases. Nederman has consequently developed the cassette-type KU cooler specifically for cooling such gases.

- Automatic Cleaning system for sticky dusts

- All elements accessed from the catwalk

- Ability to pre-heat cooling air to eliminate condensation issues

- Low-profile and compact

- No Fluids Needed

- Self Cleaning Option

- Customizable

- Small Footprint

- Fully Automatic Operation